-40%

Fiber Optic Assembly Multimode & Single Mode Connectors Epoxy Kit F112, 2.5 gm

$ 5.27

- Description

- Size Guide

Description

Technical Product BulletinFIBER OPTIC ASSEMBLY EPOXY ADHESIVE

PRODUCT DESCRIPTION:

AA-BOND F112 is an impact resistant, fiber-optic adhesive.

AA-BOND F112 is two-part, low viscosity epoxy has the distinct

advantage of remaining below 3000 cps for a minimum of 40

minutes.

AA-BOND F112 allows more connectors to be produced from one mix. Low stress, AA-BOND F112 is an excellent choice for

multimode connectors and single mode connectors

where excessive

curing

temperatures may cause cracking.

AA-BOND F112 can be cured at room temperature overnight or as fast as 15 minutes at 90°C. The blue color facilitates easy

polishing and its cured properties prevent pistoning.

This product is a

100%

solid system that can be used for small potting

and sealing applications where resistance to thermal

shock and impact are required.

THERMAL PROPERTIES:

CTE, linear

34.4 µin/in-°F

Glass Transition Temp, Tg

216 °F

Operating Temperature

-60 to 100 °C

PRODUCT CHARACTERISTICS:

Appearance

Dark Blue

Components

2 component -

requires mixing

Mix Ratio, by weight

100/30 Resin:Hardener

Benefits

·

Low viscosity

·

Thermal shock and impact resistant

·

Low stress connections

Cure Type

Room Temperature or Heat Cure

Typical Applications

·

Fiber optic assembly

·

Multimode and single mode connectors

·

Small potting

·

Sealing applications

CURE SCHEDULE:

24 hours

@ 25°C

1 hour

@ 65°C

15 minutes

@ 90°C

CURED PROPERTIES:

Glass Transition Temperature

(Tg), ultimate, °C

102

Refractive Index

1.51

Water Absorption %

0.07

UNCURED PROPERTIES:

Viscosity @ 25 °C, cps

1800

@ 25 °C, 77 °F

Thixotropic Index

1.0

Specific Gravity, cured

1.2

Pot Life

30 minutes

MECHANICAL PROPERTIES:

Hardness, Shore D

85

Adhesive Bond Strength

(Lap shear, alum to alum)

2500 psi

24 hrs @ 25°C

3000

psi

1 hr @ 65°C

4300 psi

15 min @ 90°C

GENERAL INFORMATION:

For safe handling information on this product, consult the

Material Safety Data Sheet, (MSDS).

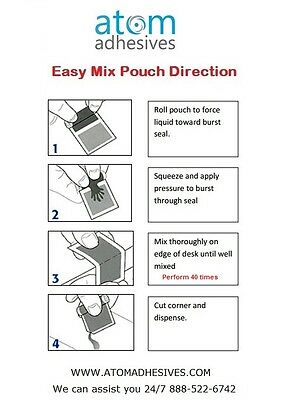

HOW TO USE:

1- Carefully clean and dry all surfaces to be bonded.

2- Apply this completely mixed adhesive to the prepared

surfaces, and gently press these surfaces together.

Contact pressure is adequate for strong, reliable bonds;

however,

maintain contact until adhesive is completely

cured.

3- Some separation of components is common during

shipping and storage. For this reason, it is recommended

that the contents of the shipping container be

thoroughly

mixed

prior to use.

4- Some ingredients in this formulation provided may crystallize when subjected to low temperature

storage. A gentle warming cycle of 52°C for 30 minutes prior to

mixing

components may be

necessary. Crystallized epoxy components do not react as well as liquid components and should be

re-dissolved prior to use for best results.

AVAILABILITY:.

This epoxy can be supplied in many different packages.

Froo www.froo.com | Froo Cross Sell, Free Cross Sell, Cross promote, eBay Marketing, eBay listing Apps, eBay Apps, eBay Application