-40%

Epoxy Staking Compound, Weather Resistant Solvent Free Pass NASA 2116, 2.5 grams

$ 5.27

- Description

- Size Guide

Description

Technical Product BulletinLOW VAPOR PRESSURE EPOXY STAKING COMPOUND

PRODUCT DESCRIPTION:

AA-BOND 2116

is a thixotropic, low vapor pressure epoxy system that passes the NASA Outgassing Specification. It is

recommended for critical electronics, aerospace, and industrial applications where a high-fill, non-sag reliable adhesive is

required for bonding and enhancing the mechanical and structural rigidity of assemblies.

AA-BOND 2116

is two-part, solvent-free compound is readily mixed, handled, used, and cured at room temperature, and

develops strong bonds to most clean, dry material surfaces including metals, glass, ceramics, wood and many plastics.

AA-BOND 2116

bonds provide electrical insulation and excellent resistance to weather, galvanic action, petroleum solvents

and lubricants, gasoline, jet fuels, alcohol, salts, and mild acids and alkalis.

GENERAL PROPERTIES:

Appearance

Milky translucent

Cure Type

Room temperature or Heat Cure

Benefits

Passes NASA's Outgassing/Low Outgassing

Solvent free

Weather resistant

Mix Ratio by weight

100:22.5 / Resin:Hardener

Substrates

Ceramics, glass to glass, fabrics, metals, laminates and other composite materials

Operating Temperature

-60 to 130 °C

UNCURED PROPERTIES:

Specific Gravity

1.25

Reactive solids contents, %

100

Pot Life

30 minutes

CURE SCHEDULE:

4 hours

@ 65°C

24 hours

@ 25°C

MISC PROPERTIES:

Volume Resistivity

6.00e+13 ohm-cm

Dielectric Constant

4.5

Dielectric Strength

410 kV/mil

Hardness, Shore D

88

GENERAL INFORMATION:

For safe handling information on this product, consult the Material Safety Data Sheet, (MSDS).

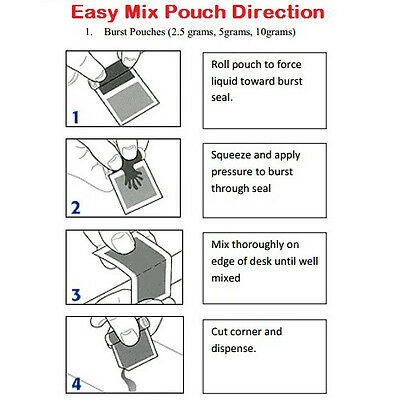

HOW TO USE:

1)

Carefully clean and dry all surfaces to be bonded.

2)

Apply this completely mixed adhesive to the prepared surfaces, and gently press these surfaces together. Contact pressure

is adequate for strong, reliable bonds; however, maintain contact until adhesive is completely cured.

3)

Some separation of components is common during shipping and storage. For this reason, it is recommended that the

contents of the shipping container be thoroughly mixed prior to use.

4)

Some ingredients in this formulation provided may crystallize when subjected to low temperature storage. A gentle warming

cycle of 52°C for 30 minutes prior to mixing components may be necessary. Crystallized epoxy components do not react as

well as liquid components and should be re-dissolved prior to use for best results.

AVAILABILITY:

This epoxy can be supplied in various different packages.

Froo www.froo.com | Froo Cross Sell, Free Cross Sell, Cross promote, eBay Marketing, eBay listing Apps, eBay Apps, eBay Application