-40%

Crystal Clear Epoxy Resin, Bar &Table Top, Coating &Casting Crafts, 1 Gallon Kit

$ 36.95

- Description

- Size Guide

Description

PREMIUM QUALITY EPOXY RESIN, Crystal Clear, Bar & Tabletop, Coating & Castings. General Use: Great for Wood, CRAFT, ART, AND JEWELRY projects.Proudly made in the U.S.A. The finished product cures CRYSTAL clear with a super high GLOSS finish. This product cures very hard, smooth, clear, and exhibits good air release. Excellent chemical and water resistance. Easy to use at a 1:1 mix ratio (By Volume) (Example 1 cup to 1 cup). We ship the same day of your purchase and will forward all tracking information once your item has shipped. Please Note: This kit is 1 gallon total. (1/2 gallon resin and 1/2 gallon hardener total 1 gallon). The resin weighs 4.10lbs. pounds and the hardener weighs 3.15 pounds.

Curing

This product provides a fast cure and property development at ambient and low temperatures without accelerators and allows for a quick return to service. The typical pot-life on this item is roughly 45-50 minutes based on mass and temperature. Thin-film set time (3mil. film) is roughly 5 hours at 78F. Fast cure and green time while exhibiting low exothermic temperatures (120C.) makes this product ideal for all applications. The full cure is 24 hours at normal conditions.

Features:

Mix Ratio

...............1:1 by volume

Work time

..............45-50 minutes (200gram mass)

Hardness

....................D78

Mixed Viscosity

..........1200cps.

Chemical Resistance.

......excellent

Moisture Resistance

........excellent

Product weight.

.............8 pounds

FDA Compliant / Food grade:

Yes, in its inert fully cured state

Approximate Coverage:

12 square ft per gallon at 1/8 inch thickness

Heat resistance:

up to 165 degrees Fahrenheit (please don't leave hot pans on it)

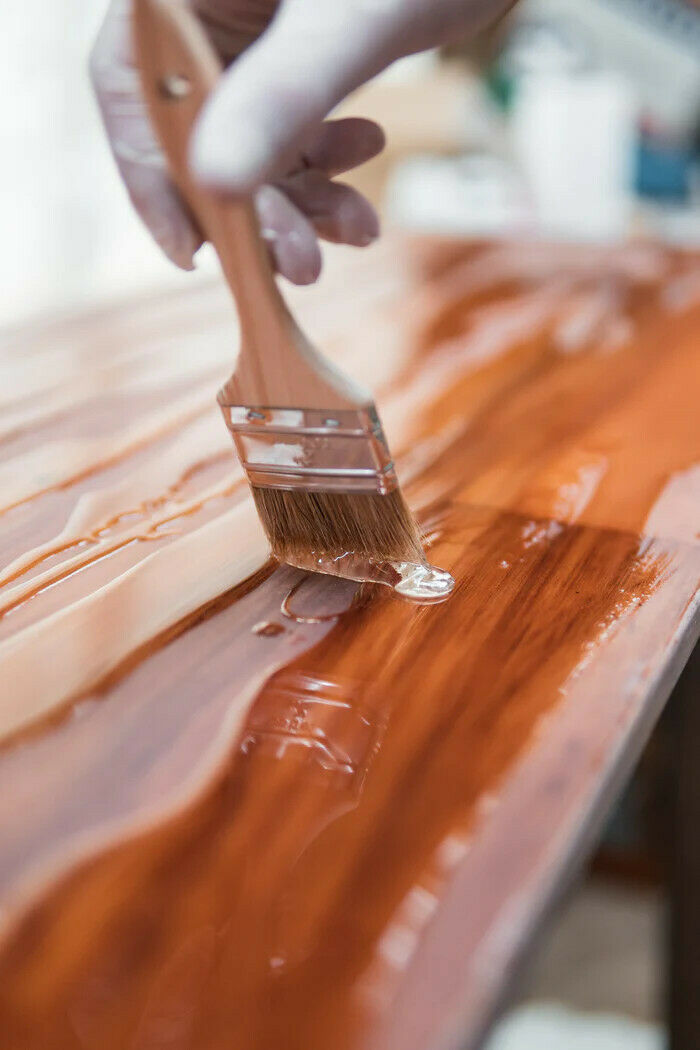

Mixing, Storage, and Application

Mix this resin 1:1 by volume (1 cup to 1 cup). If mixing by weight, mix 100 parts of resin into 83 parts of hardener. Remember that thermoset plastics are temperature sensitive. Cold weather slows the curing process down, whereas heat speeds curing up. Always try to mix chemicals at room temperature. Quick Guide: Pour Part B Hardener first into a mixing cup and Part A Resin second. Scrape the corners, sides, and bottom of the containers frequently while mixing. Hand mix with a mixing stick for at least 3-5 minutes in a round motion until mixed components are clear and free of striations. Avoid whipping or lifting mixing the mixing sticks while mixing as this may create bubbles. Allow to stand in your mixed cup for 5 minutes (allows any bubble to rise to the surface). Pour along the side of the container to help alleviate air entrapment and when pouring onto your project use only what flows out (no longer a need to scrape the sides) to avoid unmixed product onto your project.

Small castings and potting units may take longer to cure than larger items. This product needs to be stored in a dry, safe, temperature-controlled environment. Always keep the lids tightly sealed when not in use and best if used within 6-months. Remember, oxygen and moisture oxidize and can rapidly degrade the epoxy and hardener. Moisture is also a potential issue. Always keep the bottles sealed when not in use.

When applying this product, use gloves, goggles, and proper safety equipment.

Beginners Notes:

This product will produce professional results when applied correctly. Take your time to review some of these common problems that first-time users can encounter. 1. VERY IMPORTANT: To avoid most of these common problems, you should always do a trial run with the product to ensure proper understanding of how to mix and apply. 2. Always make sure that your mixing container is clean, and your measuring device is accurate. This product requires that you mix at a 1 to 1 ratio by Volume (1 cup to 1 cup). Any variances from this ratio will cause the epoxy to never completely cure. 3. THOROUGH mixing is the most important part of this procedure.

Temperature has direct impact on curing of epoxy. Around 72-77 F is the ideal range for complete and proper curing and also ensures the working area remains around this temperature for 24 hours after pouring for best curing results.

Below the 70 F will lead to longer drying times or incomplete curing. Need to use in cold environment? Place the bottles of resin and hardener in a container of warm water.

What You Need: 1) Safety Gloves - Epoxy is very sticky.

Graduated Mixing Cups - Accurate measurement is extremely important to achieve optimum cured properties.

Clean Stir Sticks - Dirty sticks can cause contamination of the epoxy.

Rubber Squeegees - These spreaders will not leave air bubbles behind as brushes can.

Brushes - Foam or nylon brushes which do not lose bristles

Solvent - Denatured alcohol or acetone for cleanup and wiping

Propane Torch, Heat Gun or Hair Drier - Used by sweeping the heat or flame across the surface of the uncured epoxy to release trapped air bubbles

Drop Cloths - Should be used to avoid spills on flooring surfaces

RETURNS:

Our goal is to provide quality products and keep our customers happy. If you are not satisfied with your purchase, we will issue you a full refund. We do ask that the buyer pays for return shipping.